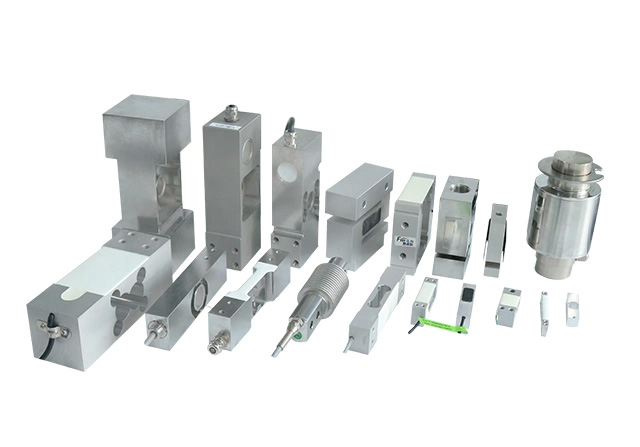

We continuously develop and produce: precision micro and small force sensors, dynamic and static torque sensors, three-dimensional force, multi-dimensional force sensors, load cells, custom ring force sensors, Rod End force sensors, tension series and various non-standard force sensors, etc.

Changzhou Uticell Technology Co.,Ltd was founed in 2009. It is located in Changzhou City, Jiangsu Province, China. It is a comprehensive company integrating load cell, force sensors and weighing instruments, as well as research and development, technical support, professional manufacturing and consulting services for weighing equipment and systems.

Uticell's technical team has advanced sensor design and production experience in China and Germany, and has profound attainments in the processing and processing of the structure and material characteristics of various foreign weighing sensors and force measuring weighing sensors. At the same time, it is rooted in the research of sensor design and manufacturing technology, strengthens technological innovation, and improves product design. Continuously introduce advanced production equipment and manufacturing processes at home and abroad, and the products continue to receive good reviews from customers and are widely favored by the market.

Our sensors use high quality materials because the quality of the material directly affects the creep of the sensor

We can customize sensors for our customers according to their special requirements and use environment

20+ years of experience in sensor manufacturing and continuous optimization of production and innovation

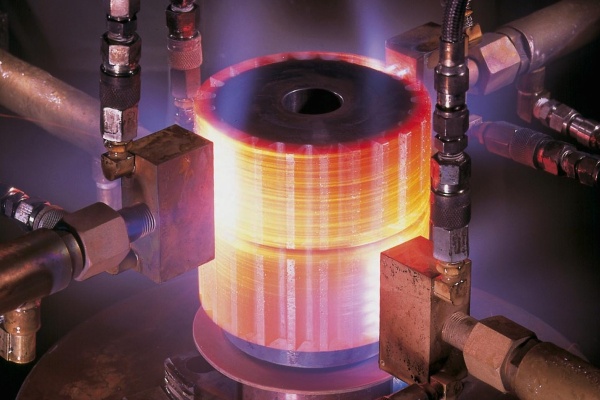

Each sensor elastomer is quenched and tempered to increase sensor durability and stability.50+ regions’ buyer feedback makes us be one of the most trustable forklift truck manufacturers and suppliers in China.

Our sensors and the same quality products have a very high cost performance,significant cost savings for customers

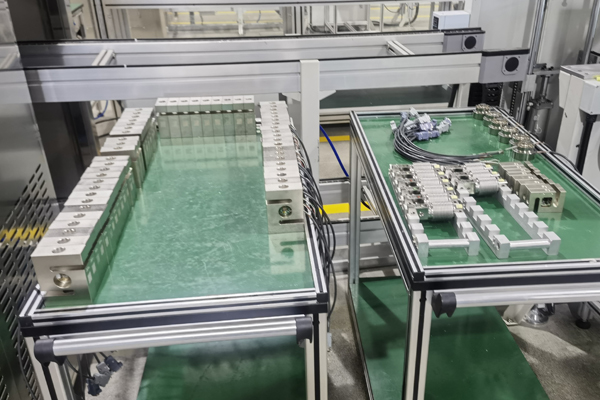

Every sensor must be rigorously tested before it leaves the factory,The factory's excellent inspection process guarantees the quality of each sensor

Since 2009, Utilcell has been providing sensors and OEM services adhering to the finest quality standards and ensuring prompt lead-time. Over the years, we have established solid relationships with numerous renowned brand owners, consistently meeting their expectations with our reliable offerings.

Our sensors are widely used in various fields such as: industrial automation, mechanical testing, load detection, medical applications, automotive industry, machinery industry, instrumentation industry, industrial automation control, weighing industry, agricultural field.

If you possess your own distribution channels for sensor, Utilcell stands as your premier manufacturer and partner in China. We are fully equipped to provide you with a range of sensor and weighing indicator,Industrial control instrument,weighing equipment.

In the field of industrial measurement that pursues extreme precision and stability, force sensors and weighing sensors are core components, and their performance is directly related to the reliability and accuracy of the entire system. The cornerstone of all this is the careful selection and continuous innovation of elastomer materials. In addition to carefully selecting materials, our company also relies on advanced manufacturing processes and a strict quality control system to ensure that each piece of elastomer can reach the best state. From the selection of raw materials, processing and molding to precision testing, every link is strictly controlled to ensure that the sensor still maintains excellent stability and reliability in long-term use.

Utilcell uses high-precision materials for the core components of each sensor, such as elastic elements and sensing elements. Choose the appropriate heat treatment process for different materials and application requirements. Eliminate and reduce internal stress through heat treatment, adjust the structure and improve toughness. By continuously optimizing heat treatment parameters and adopting advanced heat treatment technology, combined with mechanical treatment methods, the company further eliminates and releases the internal residual stress of the material, and achieves a perfect match between the hardness, strength, and toughness of the material, significantly improving the accuracy of the sensor. , stability and service life.

Utilcell selects famous domestic and foreign brands for sensor strain gauges, such as HBM, Vishay, Sony, and Zemic, thus ensuring good performance and quality of the sensor.

We appreciate your consideration and thank you for selecting us from among so many options. It's important to us that we meet your specific needs, and we're here to provide detailed information about our MOQ policies, if any, for our sensor. Please don't hesitate to reach out if you have any further questions or require clarification. We're here to assist you.

weighing sensors, micro force sensors, dynamic and static torque sensors, six-dimensional force, three-dimensional force, multi-dimensional force sensors, customized annular force sensors, threaded force sensors, threaded preload sensors, robot-specific sensors, tension series and various non-standard force sensors, Industrial control instrument,weighing indicator ,weighing module,automatic weighing system etc.

We offer a standard warranty period of 2 years from the date of purchase for our product. This warranty covers any manufacturing defects and ensures that you can enjoy your product with peace of mind

Our sensors are mainly made of 40CRMONIA alloy steel and stainless steel 2GR13, PH17-4

Yes, we accept product customization for special requirements

We need to know the following:Capacity, usage, and related parameters

Yes, We will give a discount according to the quantity purchased,If you buy a large quantity, please send us an inquiry and we can discuss the price.

Utilcell presents to you a comprehensive one-stop industrial solution. Our offering is designed to cater to all your manufacturing needs, encompassing a wide range of industrial scales:Includes floor scale, bench scales, truck scales, axle scale, crane scales, pallet jack scales and other industrial weighing systems,tailored to fit various production requirements. With Utilcell, you can expect a seamless and efficient manufacturing process, as we provide not just the scales, but also the support and expertise to optimize your industrial operations.